110.14(D) Terminal Connection Torque.

Code Change Summary: Revised code section.

Many questions have arisen since tightening torque requirements first appeared in Section 110.14(D) in the 2017 NEC®. Who verifies the electricians torque tool is properly calibrated? How does the inspector verify that the electrician torqued the terminal to the right value? Can a torqued terminal be re-torqued?

The 2020 NEC® has replaced the requirement for a “calibrated torque tool” with “an approved means” and added three informational notes for further clarification.

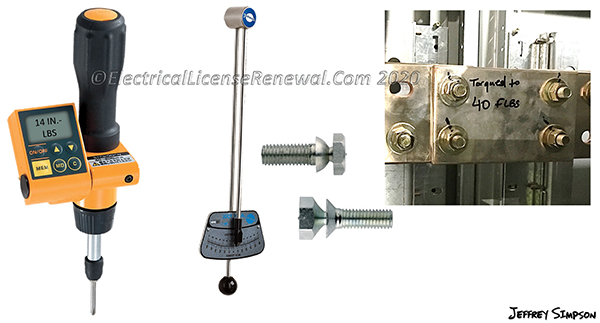

Informational note 1 states that an example of an approved means of achieving the indicated torque values can include torque tools or devices such as shear bolts or breakaway-style devices with visual indicators that demonstrate that the proper torque has been applied.

Some of the newer breakaway-style torque bolts have a visual indication that the proper torque has been applied.

Below is a preview of the NEC®. See the actual NEC® text at NFPA.ORG for the complete code section. Once there, click on their link to free access to the 2020 NEC® edition of NFPA 70.

2017 Code Language:

110.14(D) Installation. Where a tightening torque is indicated as a numeric value on equipment or in installation instructions provided by the manufacturer, a calibrated torque tool shall be used to achieve the indicated torque value, unless the equipment manufacturer has provided installation instructions for an alternative method of achieving the required torque.

2020 Code Language:

110.14(D) Terminal Connection Torque. Tightening torque values for terminal connections shall be as indicated on equipment or in installation instructions provided by the manufacturer. An approved means shall be used to achieve the indicated torque value.

Informational Note No. 1: Examples of approved means of achieving the indicated torque values include torque tools or devices such as shear bolts or breakaway-style devices with visual indicators that demonstrate that the proper torque has been applied.

Informational Note No. 2: The equipment manufacturer can be contacted if numeric torque values are not indicated on the equipment or if the installation instructions are not available. Informative Annex I of UL Standard 486A-486B, Standard for Safety-Wire Connectors, provides torque values in the absence of manufacturer’s recommendations.

Informational Note No. 3: Additional information for torquing threaded connections and terminations can be found in Section 8.11 of NFPA 70B-2019, Recommended Practice for Electrical Equipment Maintenance.