547.44(C) Equipotential Plane Construction.

Several methods are permitted to comply with 547.44(C).

Code Change Summary: New Section 547.44(C) was added to provide detailed construction requirements for equipotential planes in agricultural buildings.

SME commentary: In the 2026 NEC®, new Section 547.44(C) was added to establish specific construction requirements for equipotential planes used in agricultural buildings. Equipotential planes are defined in Article 100 as “conductive elements that are connected together to minimize voltage differences.” In livestock containment areas, these planes play a critical role in reducing the risk of electrical shock to both animals and people by ensuring that all conductive surfaces maintain the same electrical potential. This is particularly important in wet or corrosive livestock areas where concrete floors, metal gates, heated watering tanks, and other conductive equipment endure constant wear and exposure, increasing the risk of becoming energized from fault currents, lightning, or voltage gradients in the earth.

Prior to this change, Section 547.44 required equipotential planes in specific locations and provided direction on how to bond to the plane but did not describe how the plane itself was to be constructed. The new subsection 547.44(C) resolves this by prescribing acceptable materials and installation methods. This added detail gives installers and inspectors the guidance needed to apply equipotential plane requirements correctly in livestock buildings.

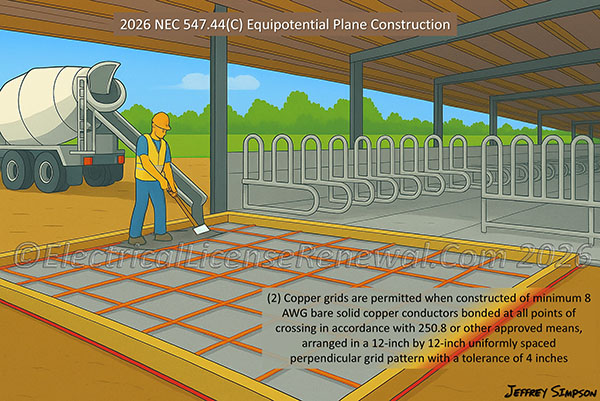

New Section 547.44(C) provides four methods of compliance when constructing the equipotential plane:

- Structural reinforcing steel. Unencapsulated structural reinforcing steel (rebar) is permitted and shall be bonded together by steel tie wires or the equivalent.

- A copper grid. Copper grids are permitted when constructed of minimum 8 AWG bare solid copper conductors bonded at all points of crossing in accordance with 250.8 or other approved means, arranged in a 12-inch by 12-inch uniformly spaced perpendicular grid pattern with a tolerance of 4 inches, and assembled using only listed splicing devices or exothermic welding.

- Unencapsulated welded wire. Unencapsulated steel structural welded wire reinforcement (welded wire mesh) is permitted if bonded together by steel tie wires or the equivalent and fully embedded within the surface material.

- Nonconductive surface provisions. If there is no structural reinforcing steel (rebar), or if the rebar is encapsulated in a nonconductive compound or if embedding is impossible, a copper conductor grid in accordance with 547.44(C)(2) must be provided directly under the surface material not more than 6 inches below finished grade.

This new code language aligns Section 547.44 with similar equipotential plane construction methods in Articles 555.14, 680.26, and 682.33, which address marinas, swimming pools, and bodies of water. By adding comparable requirements into Article 547, the 2026 NEC® brigs consistency to environments where personnel and animals may be simultaneously in contact with conductive surfaces and earth. This results in a more uniform approach to minimizing step and touch potential hazards in livestock facilities, enhancing both electrical and operational safety in agricultural installations.

Below is a preview of the NEC®. See the actual NEC® text at NFPA.ORG for the complete code section. Once there, click on their link to free access to the 2026 NEC® edition of NFPA 70.

2023 Code Language:

547.44(C) did not exist.

2026 Code Language:

N 547.44(C) Equipotential Plane Construction. Equipotential planes shall be constructed as specified in 547.44(C)(1) through 547.44(C)(4).

(1) Structural Reinforcing Steel. Unencapsulated structural reinforcing steel shall be bonded together by steel tie wires or the equivalent.

(2) Copper Grid. Copper grids shall be permitted where the following requirements are met:

(1) They are constructed of minimum 8 AWG bare solid copper conductors bonded to each other at all points of crossing in accordance with 250.8 or other approved means.

(2) They are arranged in a 12 inch by 12 inch network of conductors in a uniformly spaced perpendicular grid pattern with a tolerance of 4 in.

(3) They are constructed using only listed splicing devices or exothermic welding.

(3) Unencapsulated Welded Wire. Unencapsulated steel structural welded wire reinforcement, bonded together by steel tie wires or the equivalent and fully embedded within the surface material, shall be permitted.

(4) Nonconductive Surfaces. If structural reinforcing steel is absent or encapsulated in a nonconductive compound or if embedding is not possible, a copper conductor grid in accordance with 547.44(C)(2) shall be provided directly under the surface material not more than 6 inches below finished grade.