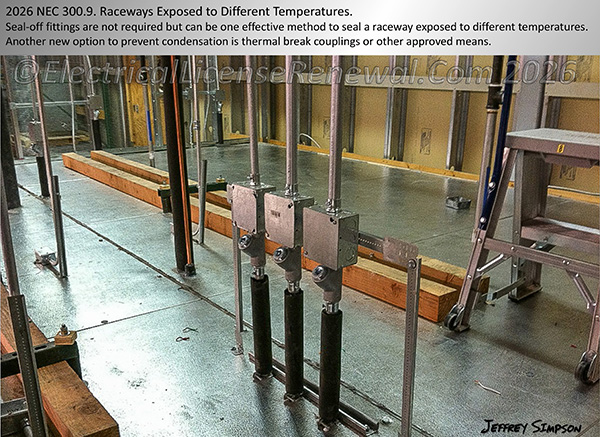

300.9 Raceways Exposed to Different Temperatures.

Seal-off fittings are not required but can be one effective method to seal a raceway exposed to different temperatures. Another new option to prevent condensation is thermal break couplings or other approved means.

Code Change Summary: Section 300.9(A) was revised in the 2026 NEC® to permit “other approved means” in addition to sealants for preventing condensation in raceways subjected to different temperatures.

SME commentary: In the 2026 NEC®, Section 300.9(A) was expanded to address a persistent issue in electrical installations: condensation forming inside raceways and sleeves when exposed to differing temperature conditions. In the 2023 edition, the rule was titled 300.7(A) Sealing and required that the raceway or sleeve be sealed to prevent the circulation of warm air to colder sections. This was primarily achieved by the use of sealants identified for cable insulation, conductor insulation, bare conductors, shields, or other components. While this approach provided a method of compliance, it did not account for other fitting technologies that could also achieve the same goal of preventing condensation.

The 2026 NEC® restructured the section, now titled 300.9(A) Condensation, and provides two distinct compliance options. The first option, found in 300.9(A)(1), retains the allowance of using sealants, consistent with prior code cycles. The second, and new option, located in 300.9(A)(2), introduces additional flexibility by permitting “the use of a listed fitting or other approved means identified for the purpose of preventing condensation and the circulation of warm air”. An informational note was added stating that a thermal break coupling is an example of such a fitting.

A thermal break coupling functions by introducing an insulating barrier between two surfaces of differing temperature. This barrier reduces the transfer of heat and maintains a more consistent surface temperature across the fitting. By interrupting the flow of heat, the risk of cold spots is reduced, which in turn helps prevent moisture from condensing inside the raceway. In practical terms, this is critical in environments such as cold storage facilities, food processing plants, or walk-in freezers where electrical raceways penetrate the building envelope. Without appropriate measures, moisture infiltration can create unsafe conditions, promote mold growth, and damage electrical equipment.

The addition of this new option acknowledges that industry practices and product standards are evolving beyond traditional sealants. By referencing thermal break couplings as a viable option, the NEC® signals to installers, inspectors, and manufacturers that listed fittings designed for condensation prevention are acceptable alternatives. This not only provides flexibility but also encourages innovation in fitting design and product certification. It also better aligns with real-world applications, where reliance solely on sealants may not be the only way to meet the intent of the code.

Below is a preview of the NEC®. See the actual NEC® text at NFPA.ORG for the complete code section. Once there, click on their link to free access to the 2026 NEC® edition of NFPA 70.

See the actual NEC® for prior text in 300.11(B) and 300.11(C)

2023 Code Language:

300.7(A) Sealing. Where portions of a raceway or sleeve are known to be subjected to different temperatures, and where condensation is known to be a problem, as in cold storage areas of buildings or where passing from the interior to the exterior of a building, the raceway or sleeve shall be sealed to prevent the circulation of warm air to a colder section of the raceway or sleeve. Sealants shall be identified for use with cable insulation, conductor insulation, a bare conductor, a shield, or other components. An explosionproof seal shall not be required for this purpose.

2026 Code Language:

300.9(A) Condensation. Where portions of a raceway or sleeve are known to be subjected to different temperatures, and where condensation is known to be a problem, as in cold storage areas of buildings or where passing from the interior to the exterior of a building, the raceway or sleeve shall comply with 300.9(A)(1) or 300.9(A)(2).

(1) Sealants. The raceway or sleeve shall be sealed to prevent the circulation of warm air to a colder section of the raceway or sleeve. Sealants shall be identified for use with cable insulation, conductor insulation, a bare conductor, a shield, or other components. An explosionproof seal shall not be required for this purpose.

(2) Other Approved Means. The use of a listed fitting or other approved means identified for the purpose of preventing condensation and the circulation of warm air shall be permitted.

Informational Note: An example of a fitting for the prevention of condensation could be a thermal break coupling.