NFPA 70E 120.5(1-6) Process for Establishing and Verifying an Electrically Safe Work Condition.

According to Article 100, an “Electrically Safe Work Condition” is a “state in which an electrical conductor or circuit part has been disconnected from energized parts, locked/tagged in accordance with established standards, tested to verify the absence of voltage, and, if necessary, temporarily grounded for personnel protection”.

Section 120.5 provides guidelines on how to both establish and verify an electrically safe work condition. See below for more details.

Below is a sample of NFPA 70E. For the complete section, see the actual NFPA 70E text at NFPA.ORG. Once there, click on the free access link to NFPA 70E.

120.5 Process for Establishing and Verifying an Electrically Safe Work Condition. Establishing and verifying an electrically safe work condition shall include all of the following steps, which shall be performed in the order presented, if feasible:

(1) Determine all possible sources of electrical supply to the specific equipment. Check applicable up-to-date drawings, diagrams, and identification tags.

(2) After properly interrupting the load current, open the disconnecting device(s) for each source.

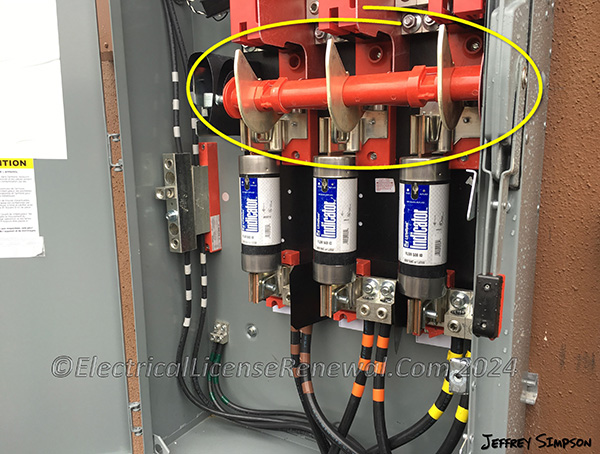

(3) Wherever possible, visually verify that all blades of the disconnecting devices are fully open or that drawout-type circuit breakers are withdrawn to the test or fully disconnected position.

(4) Release stored electrical energy.

(5) Block or relieve stored nonelectrical energy in devices to the extent the circuit parts cannot be unintentionally energized by such devices.

(6) Apply lockout/tagout devices in accordance with a documented and established procedure.