Power Distribution.

When preparing for upcoming inspections of the power distribution system (service equipment, switchgear, panelboards, transformers) make sure that the plans you are working from are identical to the city approved plans that the inspector will be referencing during the inspection.

On a large project, there will usually be revisions to the approved plans and change orders that occur. If the one-line diagram for the power distribution has changed between the time that the city approved and stamped the plans and the time of the inspection, be sure to get city approval for the revisions. If the inspector arrives to find a 3,000-amp service installed but the city approved plans show a 2,000-amp service, the inspector will stop the inspection and will not proceed until the electrical engineer has resubmitted the revised plans and the city has approved the changes. This can take days.

Be mindful of any required tests that must be documented to show the inspector.

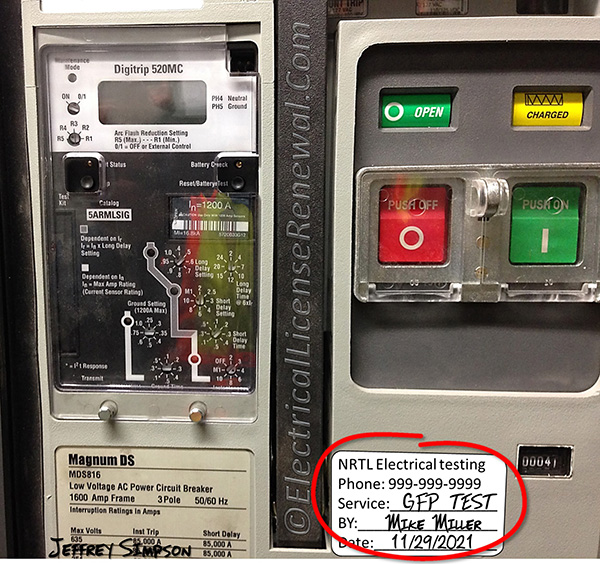

One of the most important performance tests for newly installed electrical equipment is GFPE (Ground-Fault Protection of Equipment) testing. Performance testing must be done after the system is installed but before it is energized.

Not all equipment contains a GFPE device. For each service disconnect rated 1000 amperes or more, section 230.95 requires GFPE in solidly grounded wye electric services of more than 150 volts to ground but not exceeding 1000 volts phase-to-phase. This will apply to all 480/277-volt service disconnects rated 1000 amps or more. Similar language is found in 215.10 for feeder disconnects and 210.13 for branch circuit disconnects.

When GFPE is installed, section 230.95(C) requires specific performance testing to make sure the device is functioning as intended. It is often thought that the push-to-test feature on the GFPE device is the proper way to comply with the test requirements in 230.95(C). Unfortunately, the push-to-test feature does not properly test all aspects of the GFPE device which is required in the initial commissioning of the switchgear.

For example, pressing a “push-to-test” button only initiates a test-current flow on a portion of the components, rather than all of the components that comprise the ground-fault system. It does not sufficiently test the wiring, the polarity, the current sensor primary windings, and several other critical aspects of the ground-fault protection system.

A primary current injection test must be done to test all other features of the GFPE that the push-to-test feature does not address. The inspector will usually request any code required testing to be performed by a 3rd party who will provide documentation after the testing is complete.

Some states such as North Carolina for example, amend this code section to allow the system to be tested in accordance with the manufacturer instructions rather than demanding a primary current injection test.

Below is a preview of the NEC® (NFPA 70). See the actual NEC® text at NFPA.ORG for the complete code section. Once there, click on their link to free access to the edition of the NEC® being enforced.

NEC 230.95(C) Performance Testing. The ground-fault protection system shall be performance tested when first installed on site. This testing shall be conducted by a qualified person(s) using a test process of primary current injection, in accordance with instructions that shall be provided with the equipment. A written record of this testing shall be made and shall be available to the authority having jurisdiction.